Even more so since typing this last night I somehow managed to delete the whole post. Anyways, let me fill you in since the last post.

The front windscreen trim strip is in. Yay . After the long long faff of fitting the tailgate trim strip ( 3 days of cursing and swearing then leaving the last 14" dangling free) I set too fitting the front one starting mid lower screen and working towards the drivers side ( Right hand side ).

But this time I fitted it the correct way up with the pointy edge down into the groove. These are the tools used. A careful note is don't go mad with the fairy liquid. I found it better to smear a small amount on the underside of the strip about 2 to 3 inches ahead of the fitting.

It took about 90 minutes to fit 10 inches. The angled ring spanner mentioned in earlier post was rubbish.

I even made a trim insertion tool from a thick wire coathanger, this too was rubbish. But probably I was too impatient and wanted to crack on. I left it at that for the day as the palm of my hand was killing me from the pushing and finagling. The technique was to push the top edge ( the inside edge) in, hold it, then lever the lower outside edge into the thin flimsy lip.

The following day I had inspiration. I used a mole grip to hold the trim tool and changed technique.

This time I fitted the lower outside delicate edge first and finagled and levered and pressed the middle domed part into the upper lip, levering as I went along. I got the bottom and RH vertical part in in about 60 minutes. I got the remainder done in about another 30 minutes, getting better as I went along.

So the question remains should I remove the rear trim strip and put it the corrwct way up ? Yes I will but not for a while though.

Next up was the front lights. All cleaned up and various nuts and adjusters and bulbs arrived from MGOC.

The wiring though ! That wiring, previous owner/s dodgy wiring and some illogical and puzzling switches. Firstly I had to make two good headlight bowls from two slightly corroded ones and a completely rotten one caked in 50 year old underseal.

What needed replacing was about two inches of outer rim on each plus the spring tabs at the bottom.

So after some cutting, welding and filing job done.

As a side note I fitted the dash weeks earlier, mostly, but struggled to tighten one nut on the left side. Twas then I noticed I was stripping the threaded stud poking out from the scuttle. It was not the correct nut. So I did what I normally do when faced with a conundrum and a mountain of other work to do, I ignored it.

As another side note, the wifeys car failed its mot due to rear shocks and rust in sills front left and right rear. Job done in 3 days with much welding and only a minimum of filler. Saved £ 300 I/ we didn't have so alls well and wifey joyous.

Here is the finished Left headlight showing the chrome surround spring fabricated and fixed. It took hours to make. They are only pence to buy but that was not the point, I enjoyed the process and got to work in the new shed.

Now to make sence of the wiring in the grill aperture and switches at dashboard. F@&+ me what a mess !

I had to do a lit of continuity tests with lots of cleaning and puzzling just to understand it all. Then I had to work out the switching. It might seem odd to say but I didn't really know how to turn the lights on and what were the sidelight switches. Anyway after a lot of staring at the wiring diagrams, staring at switches and the dash loom I eventually realised there was a headlight switch residing in the box reserved for the headlight refurb.

Sadly I didn't take any photos of the wiring before I commenced as I think I was too absorbed in sorting it out.

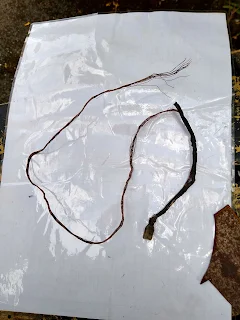

Power was flowing to both headlights then not, then to one sidelight but not the other, then not at all. The headlight switch is mounted to the steering column binnacle, in my case just dangling down into the footwell. For some reason there was an extra 8 inches of wiring going to the switch ending in a triangular type connector one end ( with just 3 wires, all red) to the dreaded terminal block the other.

After lots and lots of staring at the WD and staring at the wiring loom switch I finally figured it out.

The switch was wired wrong. Anyways I noted how wrong it was ( just in case) and rewired correctly.

Hey ho ! Headlight main beam, sidelight both sides. Then not, then the other, pppppfffftttt!

It turns out that in the grillë recess, several single bullet connectors had no inside inside the hard rubber outer covering thing. They were just pushed in from each side and hope they were touching. A bit of soldering, spade terminal crimping and done. TFFT !!

But.................on testing for some reason the drivers headlight is not on under one condition ( position ) of either the switch itself or the right column stalk position. That's for another day though.

Next up was the rear lights. The wiring was easy to follow and all there except for a few extra wires relating to the heated rear window, plus extra ones not connected to anything, all black or white.

The rear light pods I have had for years and are the correct type for pre rubber bumper cars, a little pitted but otherwise good. Cleaned, bulbs in and foam gaskets purchased and special nuts found so ready to go.

But no................... look at that boot floor. It's typical one job leads to another.

When I purchased the car the boot floor was immaculate. It looked brand new. Alas years of rear window missing, tools and stuff constantly in and out, weather and general time has taken its toll. The car was originally white but thoroughly sprayed black early on in its life.

So I decided to spruce it up before fitting the rear lights. A good Vac, clean with white spirit, areas treated with Ku-rust and applying seal sealer to inner wheel arches and a quick spray with Matt black

Lo..............it looks good and much better. It needs another coat though, but I had run out of spray.

Next up is to buy a new pair of front indicator units. I have a pair given to me when I bought the front chrome bumper. The guy gave me a box of misc lights and things, hence why I have 3 headlights, four reversing light lens's, three headlight bowls. They were all a bit cruddy but at the time I already knew I was converting to CB so I gratefully accepted them and left them in the shed for about 8 years untouched.

Sadly one indicator body is beyond redemption and rusted throughout. The other is not much better. Strangely enough it's as expensive to buy just the body as the complete unit with wiring.

That's next months purchase though so I might as well get on with the boot floor painting, rear corner boot/ wing inner area and continuity check the rear lights along with a myriad of other jobs.

My minds now made up to make it a rolling restoration and get it to a point to pass an mot.

Either way some real progress has been make and I'm determined to crack on until winter so I can save up for the interior.

More soon, I promise.