The trusty Bosch drill finally gave up the ghost.

The Draper grinder was hard to use due to the on switch always wanting to be off.

Then, after finding a Bosch grinder in the shed ( a gift from uncle Bri ) together with a drill chuck Bingo !

Alas not for long. The best wheel for getting to the corners, of which on Rostyles is many, was the acorn shaped brass wheel thing. It would only fit in the drill chuck, not the grinder, or so I thought until I discovered the above.

At that point I vowed only ever to buy Bosch tools, I was impressed by their robustness, build quality and operation. I was in love with them.

But, after using for 10 mins or so that too gave up the ghost. It was vibrating like billyyo.

With the normal wheel or the cup wheel it was fantastic, smooth, quiet and lighter than the Draper monster. The rpm of the Bosch is lower though but with the steel wire wheels it did not matter at all.

That left me with ONE of three tools, the Draper which was no good to get in the corners.

I was waiting delivery of the Bosch drill brushes and Lo, they arrived monday evening.

So after work I got to grips with replacing the brushes. It was a doddle to replace them, if not a little fiddly. The case popped apart like a dream, no broken tabs or tangs, no loose parts all stuff secured for life.

It went back together even better, with a resounding click and used all the same screws to hold it all together.

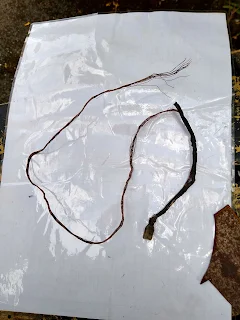

I then went on to investigate why the Bosch grinder stopped working. I had a fairly certain idea the vibration had caused a loose or broken wire.

In was correct. A wire from one of the brushes had parted company from its brass end spade. The brushes were held in by a curly clock type spring on each side. I attached a new spade terminal, attached another only this time soldered on and re- assembled. Bingo.....fast and smooth...game on.

But not tonight. Monday is the only day I work till six pm, home and fed for seven thirty and it was now nine pm.

Rather than post more pictures of wheels and tools I thought I'd outline whats been done so far, how and whats left to do on the wheels.

I started by using the drill and circular brass wheel, then brass cup. Changed to grinder with large steel wheel and paint guard for doing round the outer edges.

I tried to work in a logical and orderly fasion by doing the inside edges tops , outside edges and inner edges bottoms.

Changed to the steel cup wheel in drill for larger edges then the acorn shaped brass wheel in drill for the inner quadrants. I probably changed over several times depending on weather it was the outside or inside wheel face.

Coated with Kurust, left to cure a few days. Coated with primer and left to cure ditto. Sprayed with very bright shiney silver.

So as it stands now not one wheel is complete, yet. The intention is to get all five with paint on them ( Black gloss on inside, very shiney Silver on outside ) then give all the outsides a coat or two in Ford Nimbus grey.

Then have five new tyres fitted........yay .

Then proceed to paint the quadrants in Satin ( or matt ) Black.

Wheel one. up to speed and can wait for the others. Black inner, silver outer.

Wheel two. Kurusted and primed on back with Black gloss applied. Front primered and Silver sprayed on, badly, a few runs and some slight crazing because I rushed it a bit tonight.

Wheel three. Back kurusted, primered and black gloss applied. Partially wire wheeled old rusty primer off and applied kurust.

Wheel four. Untouced sice applying primer years ago. Needs lots of work.

Wheel five. Ditto......I think.

Thats enough of wheels for now.

I may divert onto the rear cant rail " paper mache" as its looking rather flimsy and "wavy" . I may have to use the same technique but with proper resin and mat directly onto the cant rail.

I may move on the replacing the door cards with new hardboard. I have some, but guess what, they are 2" too narrow. Pffft. Hardboard is cheap enough though. And I have the vinyl......oooooh.

Lets wait and see.

Cheers !!!!!!!!!